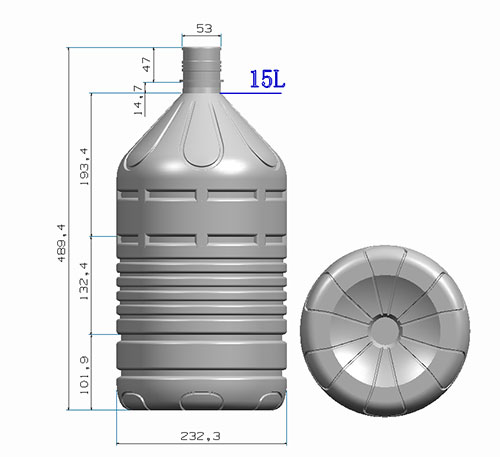

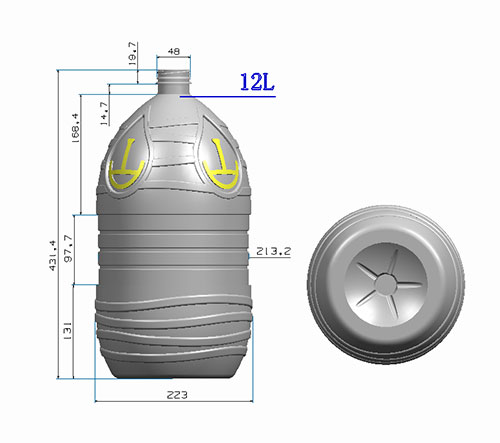

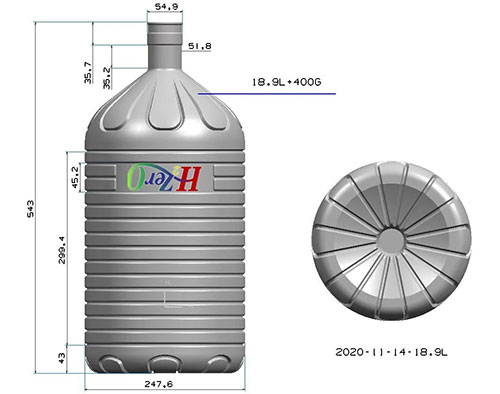

LS-B20L 1 cavity semi automatic PET/PMMA bottle blowing machine can blow water bottles, oil bottles, wide-mouth jars/cans of various shapes from 5L to 22L, especially thick-walled recycle barrels, etc.

It is a machine specially designed to blow 3 to 5 gallon PET thick-walled and thin-walled bottles. Sturdy and durable, with strong clamping force.

One-year warranty and lifetime technical support.

1.PLC& touch screen:THINGET、MITSUBISHI、SIEMENS

2.Pneumatic part: YONGCHENG、AIRTAC

3.Valve:STNC、QUANJIA、PARKER、FESTO

4.Switch: DELIXI、SCHNEIDER

5.All other accessories are from famous Chinese brands

6.Optional accessory brands

1.The machine has high stability, low noise and simple operation, requiring only one person to operate

2.Adopting double crank mold locking structure with high -hardness cast iron,the clamping force is large and durable

3.Infrared rotary oven to heat the preform ,independent temperature control and adjustable lamp for heating evenly and efficiently

4.Small size, low energy consumption and modular design makes maintenance and mold replacement easy

5.The air circuit is divided into two parts: action and blowing, which can provide stable high pressure blowing of thick-walled bottles

6.Micro PLC controller is used to ensure stable and accurate machine operation

7.Suitable for flexible production of various bottle shapes,wide application range,economical investment

|

Model NO. |

LS-B20L |

LS-B1L-4 |

LS-B3L 1 oven 1 blower |

LS-B3L 1 oven 2 blower |

LS-B5L |

LS-B5L-2 |

LS-B10L |

LS-PP |

|

Theoretical Output |

120pcs/hr |

2300pcs/hr |

1000pcs/hr |

1800pcs/hr |

400pcs/hr |

700pcs/hr |

352pcs/hr |

1000pcs/hr |

|

Max.Bottle Volume |

22L |

1.5L |

3L |

3L |

7L |

7L |

12L |

2L |

|

Max. Neck Diameter |

120mm |

40mm |

50mm |

50mm |

120mm |

100mm |

120mm |

100mm |

|

Max.Bottle Diameter |

330mm |

100mm |

100mm |

100mm |

260mm |

260mm |

280mm |

260mm |

|

Max.Bottle Height |

600mm |

340mm |

340mm |

340mm |

430mm |

430mm |

430mm |

430mm |

|

Mold Opening stroke |

360mm |

130mm |

150mm |

150mm |

320mm |

320mm |

350mm |

320mm |

|

Mold thickness |

450mm |

230mm-430mm |

240mm-430mm |

240mm-430mm |

260-430mm |

260-400mm |

260-400mm |

260mm-430mm |

|

Number Of Cavity |

1 cavity |

4 cavity |

2 cavity |

4 cavity |

1 cavity |

2 cavity |

1 cavity |

1-2 cavity |

|

Use Power |

18kw |

15kw |

8kw |

13kw |

8kw |

15kw |

12kw |

15kw |

|

Motion Pressure |

1.0mpa |

1.0mpa |

1.0mpa |

1.0mpa |

1.0mpa |

1.0mpa |

1.0mpa |

1.0mpa |

|

Blow Pressure |

≤3.5mpa |

≤3.0mpa |

≤3.0mpa |

≤3.0mpa |

≤3.0mpa |

≤3.0mpa |

≤3.0mpa |

≤3.0mpa |

|

Machine Size |

233x75x185cm 265x70x160cm 35x40x80cm |

165x70x150cm 160x100x130cm 150x220x240cm |

Blower: 167x65x170cm Oven: 175x73x154cm |

190x70x170cm 170x70x150cm |

200x90x170cm 220x70x150cm |

200x65x180cm 220x65x145cm |

145x65x170cm 420x65x145cm |

|

|

Weight |

1.8T |

1.4T |

1.0T |

1.5T |

1.2T |

1.4T |

1.5T |

1.8T |

Actual output depends on bottle shape and preform quality.

Above technical parameters are subject to continual update,please take the real machine as the base.