1. Designing the PET Bottle Blowing Mold

Discuss the process with the client and create a working concept of what they want the final design to look like.

Take into account a multitude of variables like its shape, weight, cost, and suppliers that will impact the viability and performance of the design.

Bottle shape design: making drawings of the bottle to visualize its design and dimensions.

Consulting the client: The drawings will help you decide whether you like the design or not, and then, you merely need to communicate your thoughts to use. We will revise the designs based on your comments until you’re left with a design you’re perfectly satisfied with.

Next, we design a 3D CGI model of the PET blow mould with the possibility of 3D printing the design if the project demands it. The manufacturing process starts only after a green light.

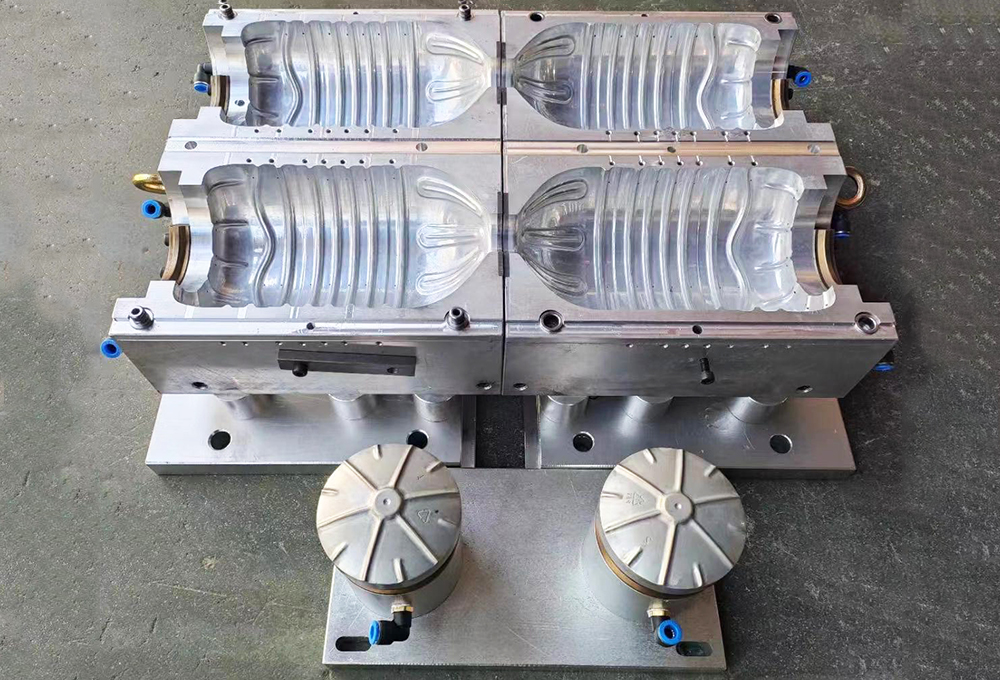

2.Maufacturing the PET Blow Mold

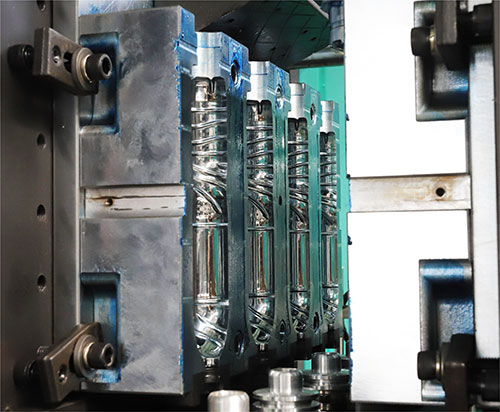

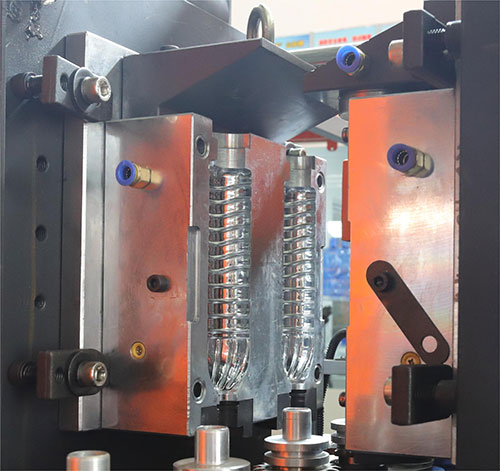

The manufacturing process starts by preparing 3D assembly drawings of the complete blowing molds including all the parts needed to install them on the PET blow molding machines. Then we order all the materials (including special types of aluminum) according to the required dimensions.

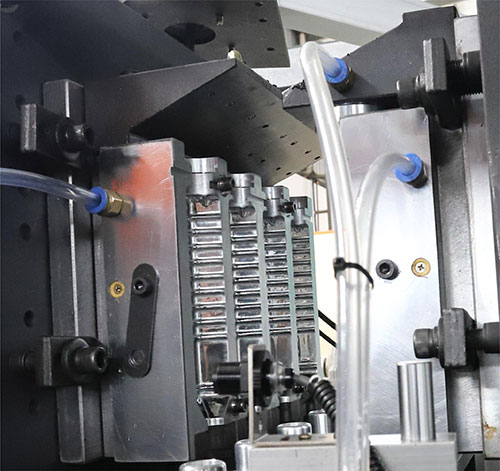

Our engineers will then write a program for CNC machines that will allow them to accurately reflect the shape and dimensions of bottles in accordance with the approved designs.

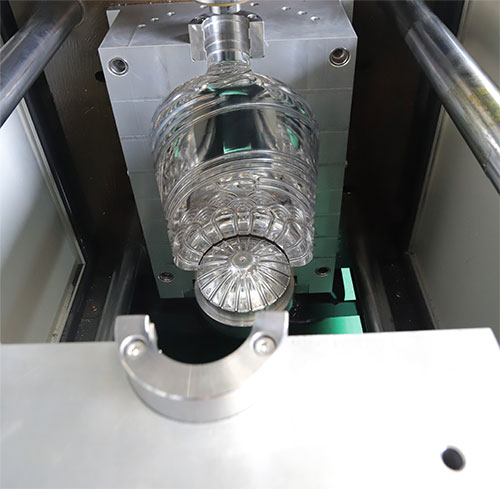

Then comes the CNC production and hand polishing of all components. After that’s done, we then assemble the molds.

3.Testing and Quality Assurance

Tests of the blowing molds on the PET blow molding machines to ensure everything works as intended.

Verifying dimensions of the physical bottle samples with the dimensions given on the drawing accepted by the client including verifying the filling level.

Handing over the molds for the PET blow molding machines to the client

|

Mould steel |

45# steel ,P20,718H,S136,7075# aluminum etc |

|

Products material |

PP bottle ,PET bottle and PC bottle |

|

Mold base |

LKM,HSACO,P20 steel,45# etc |

|

Cavity |

Single/Multi-cavity |

|

Mold life |

500K -1 millions shots |

|

Steel Hardness |

20-60HRC |

|

Lead time |

15-25days |