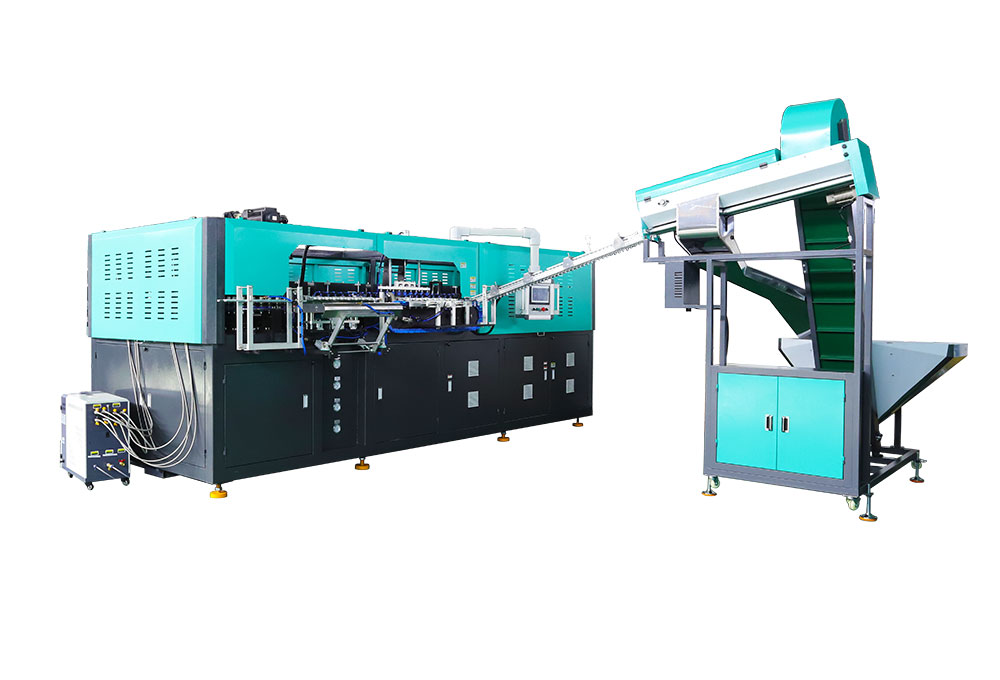

LS-F9 suitable for 50ML to 700ML drinking water bottles, carbonated soft drink bottles, medium and high temperature filling beverage bottles, milk bottles, edible oil bottles, various food bottles, daily chemical bottles etc.

Fully servo drive and the application of high speed precision blowing valve unit helps to make high capacity.

1. PLC & touch screen:SIEMENS、MITSUBISHI、DELTA、THINGET

2. Pneumatic part:FESTO、AIRTAC、SMC

3. Servo motor & driver:MITSUBISHI、DELTA、THINGET

4. Available with your favorite accessory brands

1.The variable distance transmission design and single group circulation heating system, effectively utilize the lamp heating space, improve the preform heating efficiency and energy saving effect (energy saving can reach 30%).

2.Intelligent PLC control system, easy to operate.

3.The machine is equipped with units of preform temperature detection, leaking bottle detection and rejection as well as jammed air conveyor detection etc, which ensures the machine work efficiently and stably.

4.The high pressure blowing system is equipped with air recycling device which may reduce air consumption to achieve the energy saving efficiency.

5.The machine is equipped with automatic alarm (show the cause of the alarm) and intelligent protection devices to easy maintenance and ensure safe operation.

|

Model NO. |

LS-F9 |

LS-F6 |

LS-F4 |

|

Theoretical Output |

12000pcs/hr |

8000pcs/hr |

6000pcs/hr |

|

Max.Container Volume |

700ml |

600ML |

600ML |

|

Max. Neck Diameter |

48mm |

48mm |

48mm |

|

Max. Container Diameter |

70mm |

70mm |

70mm |

|

Max. Container Height |

340mm |

300mm |

300mm |

|

Number Of Cavity |

9 cavity |

6 cavity |

4 cavity |

|

Total Power |

70kw |

55kw |

45kw |

|

Use Power |

50kw |

40kw |

30kw |

|

Working Pressure |

1.0mpa |

1.0mpa |

1.0mpa |

|

Blow Pressure |

≤3.5mpa |

≤3.5mpa |

≤3.0mpa |

|

Machine Size |

5.3x2.1x2.1m |

5.3x2.5x2.1m |

3.5x2.1x2.1m |

|

Machine Weight |

5.5T |

5T |

3.8T |

|

Feeding Machine Size |

1.5x2.3x2.8m |

1.2x2.3x2.8m |

1.2x2.3x2.8m |

|

Feeding Machine Weight |

0.3T |

0.3T |

0.3T |

Actual output depends on bottle shape and preform quality.

Above technical parameters are subject to continual update,please take the real machine as the base.