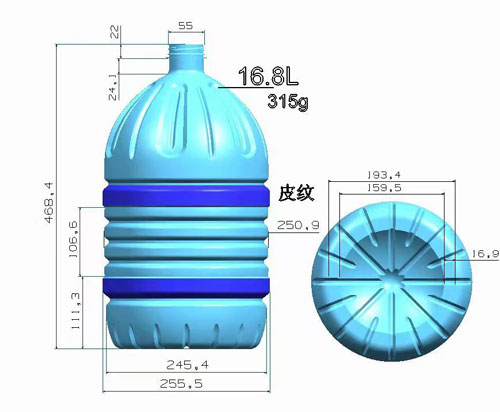

LS-A1-20L fully automatic PET bottlestretch blow molding machine is specially used to blow disposable waterbottles, oil bottles, recyclablebottles in various shapes from 10L to 20L.

It is a machine designed for largevolume 3 to5 gallon disposable and reusable water bottles and oil bottles.

The variable distancetransmission design and single group circulation heating system make the preform heating center distance smaller, heating efficiency faster, and saves more than 30% energy than traditional machines.

1.Micro PLC and touch screen:SIEMEN,MITSUBISHI,DELTA

2.Pneumatic parts:AIRTAC,FESTO,SMC

3.Stretch,move,C/O mold servo motor & driver:SIEMENS,MITSUBISHI,DALTA,THINGET

4.Electronic components from world-renowned brands with reliable quality

1.Multiple security devices to ensure smooth and continuous preform infeed without interrupted

2.Modular design saves space and effectively reduces maintenance and parts replacement costs

3.World famous brand micro PLC controller to ensure stable and precise running of the machine and easy operation

4.Modular design saves space and effectively reduces maintenance and parts replacement costs

5.The machine is equipped with automatic alarm (show the cause of the alarm) and intelligent protection devices to easy maintenance and ensure safe operation

6.Non-pause rotation and constant temperature control oven to heat preforms, saving energy

|

Model NO. |

LS-A1-5L |

LS-A2-5L |

LS-A4-5L |

LS-A1-15L |

LS-A1-20L |

|

Theoretical Output |

800pcs/hr |

1500pcs/hr |

3000pcs/hr |

450pcs/hr |

350pcs/hr |

|

Max.Bottle Volume |

10L |

7L |

7L |

15L |

20L |

|

Max. Neck Diameter |

100MM |

55mm |

100mm |

100mm |

100mm |

|

Max.Bottle Diameter |

190MM |

190mm |

180mm |

230mm |

300mm |

|

Max.Bottle Height |

400MM |

400mm |

400mm |

480mm |

480mm |

|

Number Of Cavity |

1cavity |

2cavity |

4cavity |

1cavity |

1cavity |

|

Total Power |

40kw |

50kw |

100kw |

50kw |

50kw |

|

Use Power |

20kw |

30kw |

50kw |

30kw |

30kw |

|

Motion Pressure |

1.0mpa |

1.0mpa |

1.0mpa |

1.0mpa |

1.0mpa |

|

Blow Pressure |

≤3.0mpa |

≤3.0mpa |

≤3.5mpa |

≤3.5mpa |

≤3.5mpa |

|

Machine Size |

3.0*2.0*2.0m |

4.0x2.0x2.0m |

5.0x2.3x2.0m |

3.5x2.0x2.1m |

3.2x2.0x2.1m |

|

Machine Weight |

2T |

3.8T |

6.5T |

4.0T |

3.8T |

|

Preform loader Size |

2.0x1.5x2.2m |

2.0x1.5x2.8m |

2.5x1.5x2.8m |

2.0x1.5x2.8m |

2.0x1.2x2.6m |

|

Preform loaderWeight |

0.35T |

0.3T |

0.35T |

0.35T |

0.2T |

Actual output depends on bottle shape and preform quality.

Above technical parameters are subject to continual update,please take the real machine as the base.